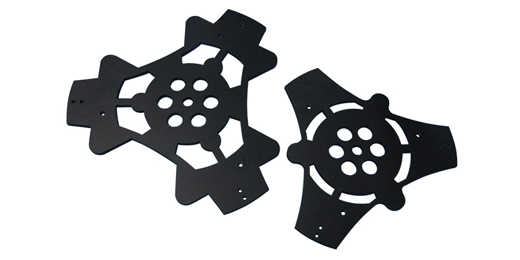

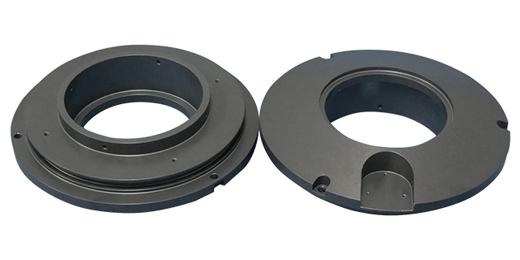

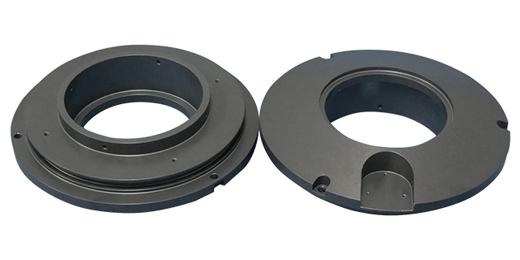

Anodizing Services

Anodize your custom parts with eMachineShop’s finishing service.

Request a quote, or design anodized parts with eMachineShop’s FREE CAD.

- 50+ Materials.

- 3M+ Parts Made.

- 15+ Years Experience.

What is Anodizing?

Anodizing protects metal by increasing the thickness of its surface oxide layer. When a coating less than 0.001” is produced, it is called standard or Type II anodizing. When coatings thicker than 0.001” are produced, it is called hardcoat or Type III anodizing. Anodizing is often used to color parts, improve durability and enhance corrosion resistance. It also provides better adhesion of lubricants to raw metal and reduces galling of threaded components. Anodizing is typically applied to aluminum, but can also be applied to other metals and dyed to almost any color.

How Anodizing Works

Anodizing works by electrolytic passivation, a process where the part being coated serves as the anode of an electrolytic cell. When this cell is electrically charged with DC current, oxygen is created on the surface of the anode, which then reacts with the part to form an oxide layer. Anodizing is commonly performed in a sulfuric acid solution.

| Satin Hardcoat Anodizing

(0.002″ Minimum Thickness) |

Satin Sulfuric Dyed Anodizing

(0.0004″ Minimum Thickness) |

|---|---|

| Black | Black |

| Non-Dyed | Blue |

| Bronze | |

| Gold | |

| Grey | |

| Green | |

| Orange | |

| Red |