Decoding the Dollars: Explaining Small Scale Custom CNC Manufacturing Costs

Have you ever found yourself scratching your head over the pricing of custom CNC manufacturing? You know, that moment when you’ve got this seemingly straightforward design in mind, but when you get the quote, it’s a bit higher than you anticipated?

Don’t worry, you’re not alone. But like many aspects of life, things might appear simple on the surface, but there’s a whole lot more going on backstage. So, let’s take a deeper look into how custom CNC manufacturing costs are broken down and calculated and why that seemingly simple design comes with a bit more of a price tag than meets the eye. And, most importantly, how you can navigate production costs to reduce the price per unit.

So let’s start with a basic look at how custom CNC manufacturing costs are broken down. It’s actually quite simple: each design has a set-up cost and a cost per unit associated with it.

To the layman, the cost per unit makes logical sense. The sheet metal design you came up with is made out of Aluminum 6061 and raw metals are not free, so there’s a cost associated with that. And it took time to cut it on the waterjet cutting machine which is operated by a skilled machinist. It’s just parts and labor, right?

While this might be an over simplified explanation, it’s not too far off. Of course there is more that goes into the pricing behind cost per unit, but at the end of the day it is the cost associated with producing your design. Plain and simple.

But what is the set up cost? What does that term really mean? And why does it have such an impact on small scale production runs?

Understanding Set Up Costs: What Does it Mean?

Set up costs in the context of custom CNC manufacturing refer to the expenses incurred during the process of preparing a new design order for production. These costs encompass a range of activities and resources required to transition from a CAD design to a tangible product from CNC machining. Set up costs include:

- Material Acquisition: This involves procuring the raw materials required for manufacturing the product according to the design specifications. The cost and delivery of these materials is a fundamental component of the set up costs.

- CAD Design to CAM Output: The CAD (Computer-Aided Design) design is transformed into machine-readable instructions through CAM (Computer-Aided Manufacturing) software. This step ensures that the CNC machine can accurately interpret and execute the design. The time, expertise, and software resources involved in this conversion contribute to the set up costs.

- Manual CNC Machine Set Up: Once the CAM output is ready, a skilled machinist undertakes the task of physically setting up the CNC machine. This process involves configuring tools, fixtures, and other machine parameters to ensure the precise execution of the design. The machinist’s time and expertise, as well as any adjustments made to achieve optimal results, are part of the set up costs.

- Labor Hours: Various labor-intensive tasks are involved in preparing the CNC machine for production. These tasks can include loading materials, calibrating machine settings, conducting test runs, and fine-tuning the machining process. The collective labor hours expended by machinists, technicians, and other personnel contribute to the set up costs.

- Tooling and Fixture Setup: Depending on the design’s complexity, specific tooling and fixtures may be required to secure the material and facilitate precise machining, such as hard or soft jaw mounts and clamps. The cost of designing, producing, and installing these tooling and fixtures forms a portion of the set up costs.

- Quality Assurance and Testing: Before full-scale production begins, quality assurance checks and test runs are conducted to ensure that the CNC machine is producing parts that meet the desired specifications and tolerances. The time and resources dedicated to quality assurance and testing are accounted for in the set up costs.

- Waste and Scrap: During initial setup, there may be a certain amount of material wastage or scrap produced as the machinist fine-tunes the process and ensures the CNC machine is operating accurately. The cost associated with this initial waste is also considered as part of the set up costs.

Essentially, set up costs encompass the various administrative and labor intensive tasks required to transition a design order into a production-ready state for custom CNC manufacturing. These costs cover material acquisition, CAD-to-CAM conversion, manual CNC machine setup, labor hours, tooling and fixture preparation, quality assurance, testing, and any initial waste or scrap. Understanding and managing set up costs is crucial for optimizing production efficiency and cost-effectiveness in CNC manufacturing processes.

So now that we have a better understanding of the unavoidable costs associated with custom CNC manufacturing, how can we help mitigate these costs and maximize cost efficiency?

How Scaling Quantities Affects Cost Efficiency

It may sound obvious, but ordering in larger quantities significantly increases cost savings due to economies of scale. This concept is based on the principle that the more units you produce, the lower the cost per unit becomes. Let’s explore how this applies to custom CNC manufacturing:

-

- Reduced Setup Costs: While the initial setup costs remain constant, they are spread out over a larger number of units when ordering in bulk. This means that the impact of setup costs on each individual unit decreases, making each unit more cost-effective.

- Optimized Machine Operation: CNC machines are efficient at producing multiple units in succession. When producing larger quantities, the CNC machine’s operation can be optimized, reducing downtime between setups and maximizing the utilization of resources.

- Bulk Material Purchases: Ordering materials in larger quantities often leads to volume discounts from suppliers. This directly lowers the material cost per unit, contributing to overall cost savings.

- Efficient Labor Allocation: With larger orders, labor costs can be distributed more efficiently across the production process. Skilled operators and technicians can work on a continuous production run, streamlining the manufacturing process.

What does it all mean to the end user?

Ultimately, the biggest take away here is that initial set-up costs for custom CNC manufacturing are unavoidable. Furthermore, each design has specific parameters which dictates a unique set up cost for production. Simpler designs will have lower set-up costs, while more involved designs will have higher set-up costs, but they are always there. The best way to drive the cost per unit down, is to scale up production.

For example, if the part you want to produce costs $5 a unit but has a set-up cost of $100, then your cost for 1 unit will be $105. If you want to make 100 units, then your total cost for units will be $500 + $100 set up cost = $600 total or $6 per unit. The set up cost of the latter remains the same but is distributed across 100 units instead of just one, which significantly reduces the cost per unit and all around cost savings.

In short, if you want the most bang for your buck, it might be worth considering scaling up your production run.

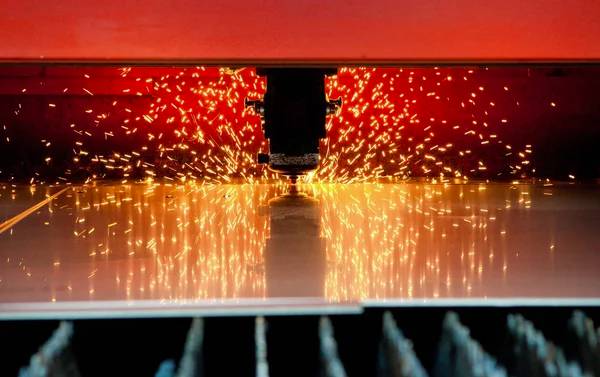

Hopefully, now you can better understand the associated costs that go into manufacturing custom CNC production runs, and that while something, such as a “simple” 2D laser or waterjet cutting project, may appear to be straightforward in concept, there’s actually a lot of moving parts, and processes behind the scenes that need to be accounted for. As it turns out, custom CNC manufacturing calls for unique methodologies to make sure your design is made within your specification and that is typically represented in the set-up cost.