Standard Specs and Tolerances

Below are eMachineShop’s default size and position tolerances and finishes that apply unless otherwise specified.

Sheet metal and sheet plastic parts

Metal: +/- .01″ for thickness < .5″; +/- .02″ for thickness > .5″

Plastic: +/- .02″

Holes < 2″ +/- .005″.

For parts with bends, the above applies to the flat sheet before bending.

Upon request, tolerances down to +/- .001″ for metal and +/- .005 for plastic are available for features up to 3″.

Machined parts

Metal: 0-12″ +/- .005″. 12-30″ +/- 0.01″. >30″ +/-.020”; Double values for plastic; Triple for Teflon.

Edge breaks: .005″ to .015″

Fillets at bottom of pockets: .003″ to .015″

Angle: +/- 1 degree minimum

Other Processes

For 3D printing, please review the chart on this page.

For injection molding, rapid prototyping and other non-machining processes, please see their respective web pages.

Surface Finish

Machined parts are as-machined. Vibratory tumble is available upon request.

|

|

|

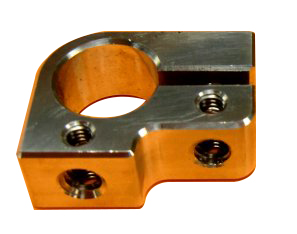

Vibratory tumble Tumbling removes sharp edges and burrs and may be more economical as it does not require machining chamfers to avoid sharp edges. (Chamfers were machined in this example.) |

As machined This finish is as-machined. |

Note that the above images are samples only – actual results may vary.